How to Start an Auto Repair Workshop

2016-12-17auto repair toolsauto shop equipment listauto suppliesauto toolsauto tools shopauto tools wholesaleauto workshop equipmentautomotive equipmentautomotive equipment and vehicles (2004) ltdautomotive equipment depotautomotive equipment groupautomotive equipment internationalautomotive equipment serviceautomotive tools equipmentautomotive tools listautomotive workshop equipment listcar accessories shop name listHow to Start an Auto Repair Workshopworkshop tools name list

The Right Equipment and Premises to Start an Auto Repair Workshop

Ready to open an auto repair shop?

Starting your own automotive repair shop or automotive workshop is the dream of good mechanics everywhere. I have lived that dream.

If you are a highly skilled and versatile mechanic, you may find it to be very restricting working for someone else when you could be running your own business and making real money at the same time.

The right equipment is essential to opening an auto shop. It takes a good knowledge of workshop equipment to make all the right decisions and you also need to learn using and maintaining different equipment correctly.

A good automotive shop equipment company will ensure you have all owners and parts manuals as well as service directives for all the heavy equipment you purchase or lease.

The company should also be capable of providing any training necessary to operate each machine safely. Most will do so for free and on site.

People skills are paramount in this business and a caring helpful personality as well as a love for your job are prerequisites when starting an auto repair shop the right way.

If you care about your work, customers will care about using your workshop to do all their mechanical repairs and servicing, so you need the right tools and equipment to do a broad range of work.

If you love what you do and want to do it for yourself, I say go for it!

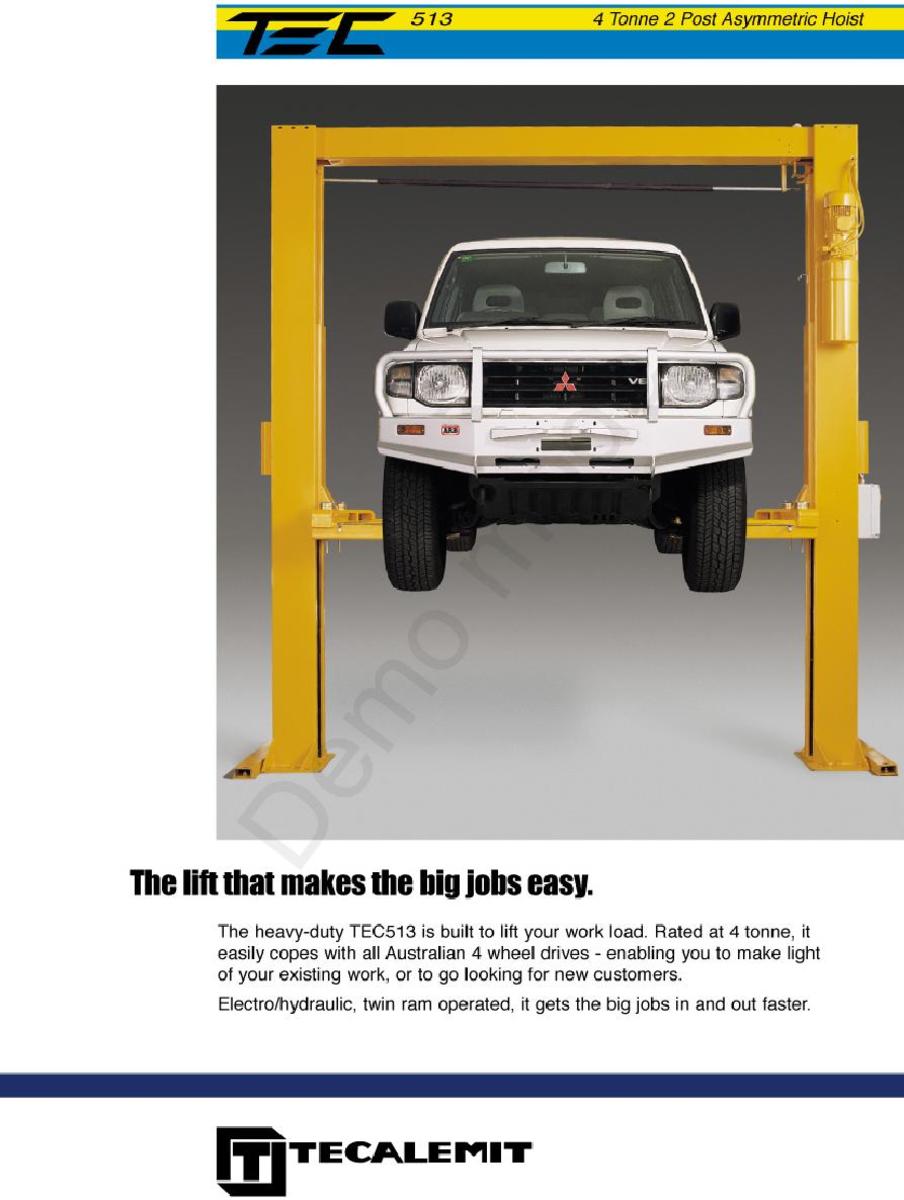

Quality hoist

You will need some cash for setting up the building lease, and painting your floor, signwriting etc and buying or leasing equipment, ( In western countries between $20,00 and $100,00 is the usual cost range for setting up a small shop to a larger operation with 4 lifts.

You will already have heaps of enthusiasm talent and skills to do the work, and have the patience to learn about setting up with the right premises machinery and equipment.

Having said that, I started my first workshop out of a leaning ricketty old shed at home that would hardly hold one car. I know of others that have done the same. Like most things, it depends on how badly you want it!

The more markets you can cover the better, so having a wide range of profit centres provides better turnover and more profit safety providing you do not spend more on machinery than you should for your market size.

Frankly, I always go after providing a wide range of services and free advice to keep them in my shop rather than having to send them elsewhere to have their air-conditioning recharged, their discs skimmed, or their wheels aligned etc.

Taking alignment work and then outsourcing it is time consuming, provides only small profit and takes time to deliver and pick up your customer’s car from the alignment centre.

You can now do alignments without a 4 post hoist using up a lot of space. The best of this equipment is expensive, so I suggest leasing your equipment if you have a good credit history.

Workshop premises.

The building needs to have the following features.

Wide access.

- Customer’s cars need room to drive in straight then go out straight to get on and off hoists unless the building is very deep, there will be no room to align the vehicle with the hoist if access is too narrow.

- If space is very limited, you can use rolling jacks that sit under the tire to maneuver the vehicle by hand. These are quick and easy to use. If your floor is in good condition the vehicle will roll sideways, back or forward with just a gentle push.

A high roof and solid 6″ floor.

- to accommodate the latest clear floor hoists you need close to 15′ from floor to ceiling..

- A 6″ concrete steel reinforced floor is required to solidly mount the hoists to.

Enough space and facilities.

The workshop floor area needs to accommodate at least 2 hoists ( if specialising)

You may consider a 4-6 hoist businesses are the sweet spot for general mechanical repairs and servicing when you have become comfortable with finding quality mechanics to work for you.

Remember to ensure the building is deep enough so you can back each car off the hoist INSIDE the building.

Reception, office, toilets and lunch room need not be big, but should be neat and comfortable for workers and customers. A water fountain is a good idea in both reception and lunch room.

Natural light.

A good natural light source is a huge advantage to your mechanics, especially for examining stains on cylinder blocks left from fluid leaks and other hard to see indicators of underlying faults.

A tiny split or damage to a hose could, if left unnoticed result in engine or gearbox damage. Engineered components like wheel bearings, crankshafts etc. where metal surface condition is the first indicator of part failure. All these important visual signs require good natural light.

Good lighting is still one of the major factors missed in auto repair shops. I have insisted on good natural light in all my workshop buildings. The better informed and more experienced mechanics will insist on natural light. Take my word for it and thank me later, as far as I am concerned this is essential to good engineering, and I want the best for my customer!

All walls bright white and at least two coats. I prefer high quality gloss myself as it is brighter than other surfaces and easier to keep clean.

Permits, oil and fluid systems, drains etc.

In most countries, states and territories there are regulations and zones where you can put a workshop.

- Make sure of the zoning first on any property you consider leasing or buying.

- Ensure you have correct drainage installed in case of large oil spills.

- Ensure that you can store volatile chemicals associated with your trade.

- Ensure you are able to operate all your machinery legally.

- The electricity supply for much workshop equipment is 400 volt 3 phase, ensure it is connected and working properly. Often you will find 3 phase wiring with the polarity changed from plug to plug. This is a darn nuisance and confuses a lot of workshop equipment!

- Install air hoses overhead. You don’t want air hoses running across the floor, in the old days grease was run this way to. If you are working on older cars with grease points install grease overhead too.

- Run an overhead waterline as well if you feel you need it for some special jobs you may do. Power points should be well above bench level so they do not get knocked, and you need plenty of them even for a basic workshop.

- Buy and maintain an emergency spill kit.

- Fit fire extinguishers to a well constructed plan, ensuring locations will be quick and easy to reach.

Painting the floor.

The workshop floor is very very important. More so than in most businesses as it must withstand stains from dirty thin and hot oil. It happens that spills do occur when doing oil changes, but more about how to stop that happening later.

BEFORE you move your hoists in, you need to know that the floor is level, thick and strong and most important, treated or painted so that the oil does not soak into the concrete and weaken it, especially around the hoist uprights.

Ensure the painted floor surface is skid-proof and smooth to roll equipment on.

Use a non skid paint. You can get one that can be rolled on or sprayed.

Four post hoist with jacking beam.

Nice clean well setup workshop

Standard Equipment.

Hoists.

Never even consider buying a cheap hoist!

I spent two years rebuilding, installing and servicing hoists. The average life of a cheap hoist is around two years before downtime and major repairs. Despite what your equipment supplier says, cheap hoists are dangerous, and when they need rebuilding parts are often not available.

The type of hoists you choose is most important, as it depends on what work you will be doing most, but at least one hoist should be a clear span or clear floor design.

A clear span or clear floor hoist as it is also known, means simply that there is nothing on the floor connecting the two sides of the hoist together.

- If you are removing and replacing components or even doing oil changes, having a clear floor to wheel your equipment around on is safer by a mile, and a lot easier to avoid spills or gearboxes falling of the gearbox hoist because it fell over when it hit the obstruction which is on all other types of hoist.

- If you are doing suspension replacements and repairs, you will need a four post hoist with inbuilt hydraulic ram for lifting the wheels off the hoist.

- The same hoist should be ordered with rotating wheel alignment plates built in, if doing wheel alignments as well.

benches.

I try to use as much wall space as I can for benches, but it does depend on where you decide to get your profit from, which I will discuss later in this hub.

Basic mechanic’s Tools.

Hand tools, such as circlip pliers, bearing pullers, ring and open end spanners, depending on what you work on this will vary, but need to be in complete sets. A full range of inside and outside circlip pliers is essential.

Hand held mechanics lamps, air guns and lines, rolling oil pans, Cooling fluid pans etc. One set for each hoist.

Other special tools for different makes and models where required, a minimum of two good quality vices. There are many more items, so I will provide a list.

Simple pipe bender.

Pedestal drill

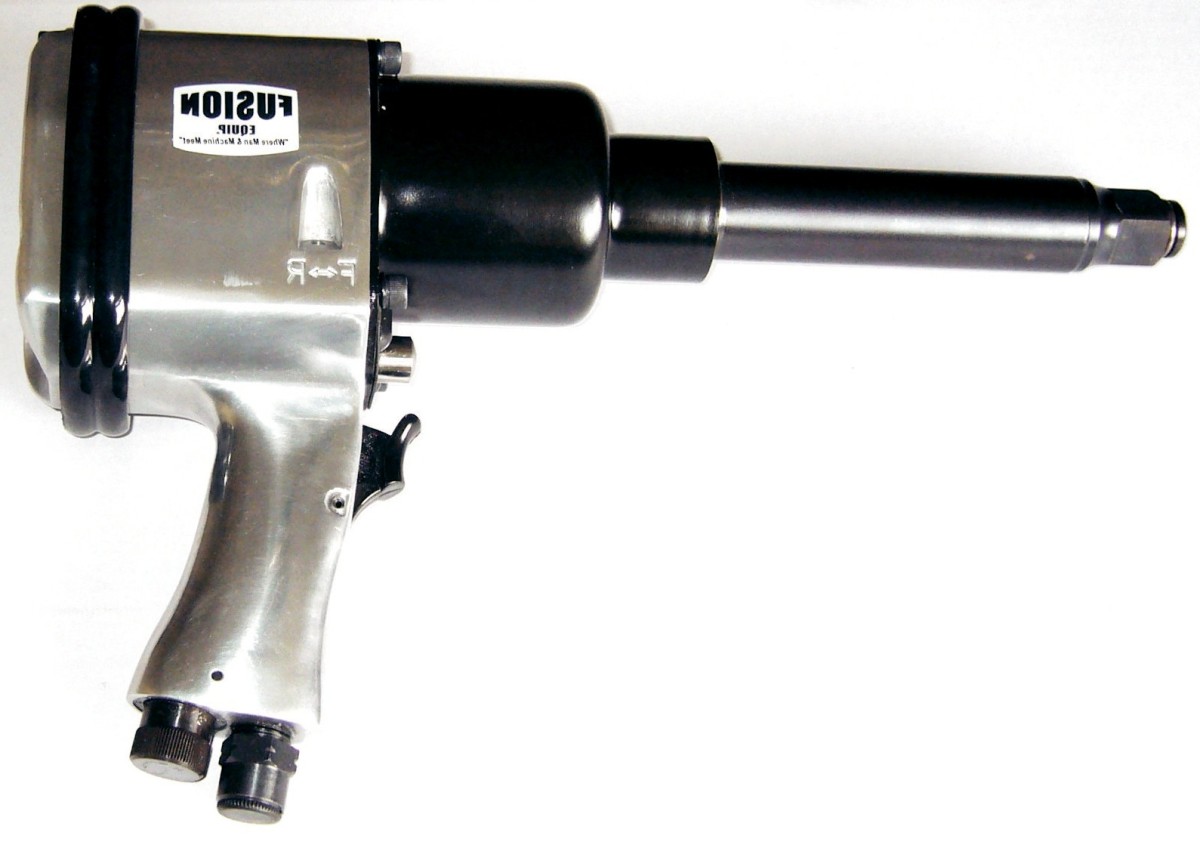

Air tools

Brake lathe

New Ammco 4000

Tyre changer with assist.

Wheel balancer.

Ammco brake lathe

Cooling system tester

Profit centres.

GENERAL WORKSHOP MACHINERY.

Tyre changer

Tire changer accessories

Tire pressure gauge

Air Pressure Regulator

Tire lever

Tire lever protector

Wheel balancer

Wheel balancer accessories

Wheel weight pliers

Brake lathe off car

Brake lathe on car

Brake lathe accessories

Wheel aligners

Wheel ramps

Engine analyser.

5 gas suitcase type if I had to choose. (I have another hub on these.)

Hoists

1X 2 post symmetric hoist 4 ton capacity (SUV’s, light trucks and vans)

1X 2 post asymmetric 4 ton capacity

1X 4 post standard hoist preferably with one jacking beam, or…..

1X 4 post alignment hoist with turntable inserts, cover plates, long approach ramp and 2X jacking beams if you want to include wheel alignment in your workshop.

belly lift quick, small, portable, fast where you want all four wheels of the ground in a hurry to change wheels, brakes, wheel bearings etc.

motorcycle lift if you do motorcycle engine rebuilds you need one of these.

SPECIALITY WORKSHOP MACHINERY

Flywheel grinder

dynamometer

Metal lathe

Injector cleaner

GENERAL WORKSHOP EQUIPMENT

Hose reel, Bench grinder, Compressor, Grease kit, Oil drainage pump, Oil extractor, Jacks

(Bottle, Vehicle positioning, Axle, Trolley, Racing, Long stroke, Transmission jack

Press, wheel stands, Axle Stands, Ratchet, sockets, Under hoist drainers, Parts washer

Pedestal drill, Pressure washer, Engine crane, Engine Trolley, Engine stand, Vacuum cleaner

Welding equipment, Wheel dolly, Work trolley, Work benches, mechanics work seat, angle grinder, Creeper, Oil drainer, Vice, Safety Light, Radiator drainer,Filter crusher.

Other handy machinery and tools..

Oscilloscope,Air tools, Impact wrench, Ratchet wrench, air cutter, hand drill, toolbox

Porta power, Car dolly, Oil/water separator

SPECIALITY EQUIPMENT

Body repair kit

Pipe bender

Pulling ram kit

Body straightening kit

Injector cleaner

Sand blasting cabinet

Spring compressor

Brake drum handler

Hydraulic gear puller

Hub tamer

Tyre spreader

Cooling system pressure tester

Fuel injection test kit

Pressure brake bleeder

Brake fluid tester

LVT

LPG

GENERAL HAND TOOLS

Measuring tools – callipers

– micrometer

– Dial gauge

– tachometer

tap& die set

SPECIALITY HAND TOOLS

ELECTRONIC TEST EQUIPMENT

Battery

Jump starter/ Tester/ Charger

Multi-meter

Test light

Armature growler

AIR CONDITIONING

Leak detector

SAFETY EQUIPMENT

Goggles

Ear protection

First aid kit

Fire extinguisher

Spill kit

Signage

Oscillating fan

Exhaust extraction reel

Servicing and installations.

Hoist maintenance/ Electrician/ Installation

Lighting design

Electrical equipment testing & tagging

Machinery repair and maintenance.

4-5 gas analyser.

Other equipment.

To work on modern cars, you need a good scanner and a 5 gas analyser, along with many wiring harnesses interface cables for the different makes and models connections to the scanner.

None of this equipment is cheap, because quality is paramount . I have sold, repaired and serviced both cheap and well designed and built ones. The cheapies will save you a grand or so, but you will regret buying either a scanner or 5 gas analyser cheap!

There is an equipment list added to this if you are doing petroleum/gas conversions, but it is not usually extensive or expensive.

Brake measuring calliper

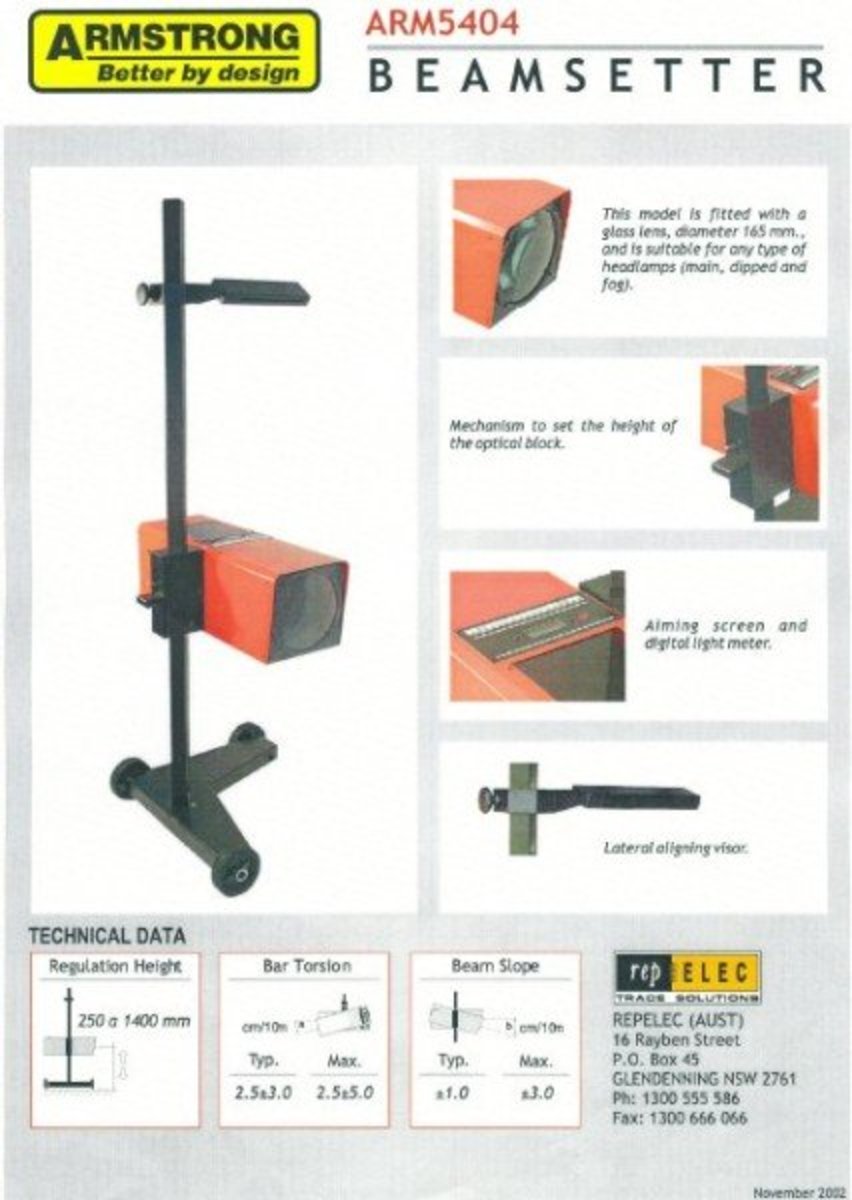

Headlight aimer.

Stand press.

Brake drum calliper

More equipment.

If you intend to get a licence to test cars for road-worthiness. (This licence has different names in some countries) You will also need quite a bit more equipment.

Headlight aimer.

Large vernier calypers.

Compression tester.

Gas analyser.

The list varies from state to state. country to country.

Profit centres.

A workshop that can do everything in-house will attract more customers, and if you cannot do a job because you do not have the necessary equipment or machinery, you need to outsource it.

Never send your customer away, ALWAYS have a solution by using other specialists to do the work for you, then check it thoroughly when it is finished and then add value.

Here are some ways to make your workshop more profitable.

- Buy a high quality brake lathe and learn how to use it. Your equipment supplier should be able to train you or your mechanic in using the equipment they sell.

Good disc machining is a matter of tooling up carefully and finishing the surfacing with a fine skim after the cut if needed.

-

Air-conditioning repairs.

Buy a multi unit that does the whole job.

-

Tyre changing, wheel balancing.

Combine with tire sales, or outsource tires. Buy a machine that will do new cars with large wheels.

-

Wheel alignment.

Equipment is expensive to buy, you need an alignment machine and an alignment hoist like the 4 post listed above. The profit on wheel alignment is not great generally, but it does attract other sales very well.

-

LPG conversions.

If you have all the equipment needed such as a 5 gas analyser and a gas fitters licence there is good money in conversions. Take your time with the re-tuning and calibration.

CINA AUTO PARTS for repair equipments with price for workshop